3D Printed 6-String Electric Violin

This video was created for the University of Texas by Skylark Creative. It was awarded Best Performance, Best in the Free-Form Category and Best in Show at the ARLies Film Festival.

During my time living in London I discovered publishing houses, I would walk in and ask for new music to perform. My favorite memory from this was when a publishing house employee dropped a massive stack of violin concerto scores in front of me and said "good luck." Here I discovered the composers Ken Hesketh, Simon Holt, Craig Armstrong and Fazil Say but most importantly I found a piece written by American Composer John Adams called The Dharma at Big Sur. It was incredible and I had to perform it. The only problem was that it was written for 6 string electric violin.

The University of Texas, Austin has 3D printers in their fine arts library and I needed a rare violin. The idea was to create a violin specifically for The Dharma at Big Sur. I put together a team to help design the violin, Daniel Goodwin to design and Rebecca Milton to use the basic violin as a canvas in which to push the design process even further. The final piece of the puzzle was the Rainwater innovation grant.

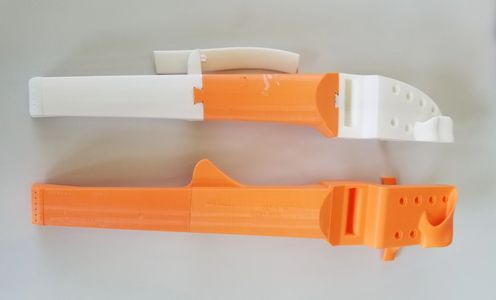

Our first design gave us a good idea of how to make a violin. Daniel's amazing knowledge and skill helped the process move along quickly. Notice the odd coloring, the library had a strong policy on changing filament (the plastic) colors on their printers. We did not place the strings on this model due to the design being too weak to support the pressure.

The six string violin is essentially a plastic instrument so I needed a way to address the sound quality. After exhaustive research I discovered Barbera Transducers. Handmade, this piece of equipment is incredible. I wouldn't have an instrument with such a high quality sound without it.

Our sculpting artist, Rebecca Milton, asked us to gather items we felt might represent The Dharma at Big Sur.

From this collection, we chose a timeworn piece of wood Daniel had discovered while hiking in California. Here you can see us 3D scanning the object. After it finished scanning we fit the object to the 3D design of our violin, printed it, and will soon be casting it in porcelain. After more experimentation she ended up using four separate cow ribs in the final instrument. I've posted this particular photo because of how cool this technology is.

Our second design had some significant changes. Interestingly, our first design melted from being left in a car. Additionally, the plastic used in the print bends over time due to the pressure added by 6 strings. The second design addressed both of these problems and we managed to convince the library to allow us to print in one color. The only available color was orange. Hook em horns.

We decided to place the strings backwards on the violin. The tuners are on the other end. Notice the thickness of the F string in comparison to the E. I had to drill a larger hole for the F string due to it's enormous size. I broke my drill bit the second time I tried this right in the middle of filming for the documentary.

This second model was the instrument on which I learned to play a 6-string violin. It's a completely different beast that's significantly wider for the left hand and I had to completely relearn how to use my bow arm.

UT discovered out project fairly early on and the College of Fine Arts wrote an article on the violin. This spread to the main university and finally the library who began making a documentary about our process.

This photo shows our first experiment with attaching the sculpting artists porcelain creations for the instrument.

We began to do our final interviews as we neared the finish line. The guys at Skylark Creative were excellent across the board, they had me sitting in the middle of this empty concert hall surrounded by lights. However, right before this interview disaster struck and I snapped a section of the violin with my elbow in the middle of a taping.

What do you do if you break your 3D printed instrument? You print another one with the press of a button and in the morning you're back in the game.

I can't adequately describe how it feels to hold an instrument you helped build from scratch. I'm incredibly proud of my team, Daniel Goodwin and Rebecca Milton. This violin looks nothing like a standard instrument yet plays and sounds like a dream.

Since the launch of UT's mini documentary on the violin, it's been viewed a few million times and featured on a large number of news, tech and music websites. Discovery Channel Canada featured the project on their show Daily Planet, Hong Kong News ran a segment and performance requests started to roll in.

This is only the beginning. I'm exciting to see where this creation will take me. My next goal is to have more music written for the instrument. Thanks for reading!

Copyright © 2023 Sean Riley Violin - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.